The High Performance supply chain

Supply chains are under pressure. The pandemic has highlighted the limits of traditional SCM processes and exposed the vulnerabilities of international supply chains. And we are already facing the next test: the consequences of the war in Ukraine. Additionally challenged by new regulations as well as rapid technological development, companies often resort to short-term partial solutions to cope with the acute challenges - with mediocre results. SCM can determine the success or failure of companies and must therefore be at the top of the strategic agenda.

Our high performance approach to supply chain management ensures that weak points are eliminated along the entire process, from the buyer to the supplier to the customer, and that the SCM organisation is linked to the corporate strategy - for an effective, agile and resilient supply chain.

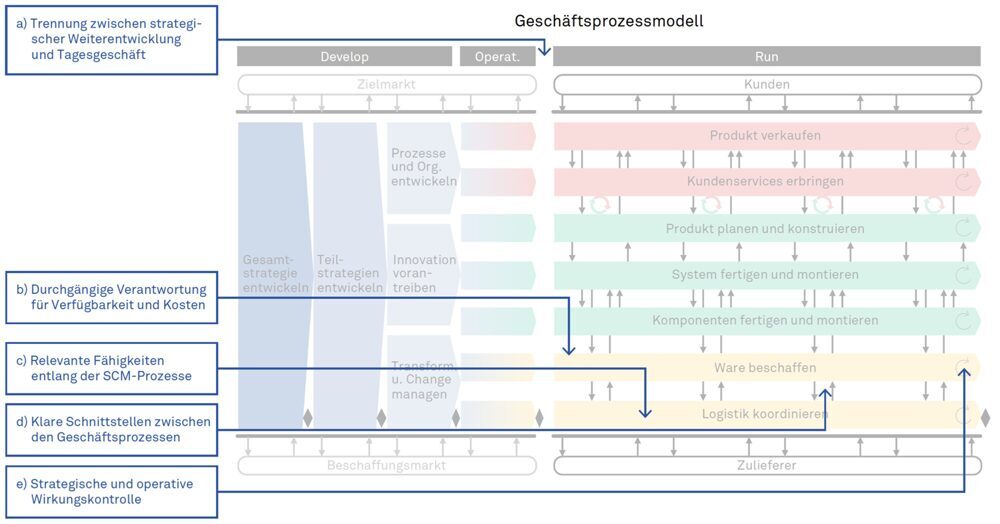

Fig. 1: Advantages of the High Performance Supply Chain

Design criteria of the High Performance SCM

The strategic and operational activities of SCM are systematically embedded in the business process model. The design of strategic development (Develop) creates the foundation for a high performance SCM - the design of the day-to-day business (Run) ensures operational excellence. The influence of the strategic activities on performance is often underestimated: according to our experience they are responsible for up to 80% of the incurred costs. The design criteria of the High Performance Organisation help to exploit the full potential of supply chain management.

a) Separation of strategic development and day-to-day business

The separation of strategic considerations and day-to-day business enables a quantum leap towards high performance SCM. Strategic procurement and logistics planning defines the necessary foundations that enable smooth operations in operational procurement and logistics.

b) Consistent responsibility for availability and costs

Clearly assigned end-to-end responsibilities are elementary for effective SCM processes. Procurement and logistics are responsible for the availability and costs of the purchased goods, coordinated with production. They are measured against this using clearly defined metrics.

c) Relevant skills along the SCM processes

The business processes of procurement and logistics are characterised by clear capabilities to meet the requirements along the process and to enable an optimal division of tasks. Tasks, responsibilities and capabilities are in harmony.

d) Clear interfaces between the business processes

There are clear principal/contractor relationships between production and procurement as well as between procurement and logistics. The same applies to the interfaces with suppliers.

e) Strategic and operational impact monitoring

Strategic impact controls are anchored in "develop", operational impact controls in "run". Closed learning loops, both within and between "develop" and "run", ensure full exploitation of the potential for further development. They form the basis for a learning organisation.

Fig. 2: Design criteria supply chain management

Current fields of action in supply chain management

For a sustainable high performance value chain, it is crucial to find the right balance between increased customer value, increased process efficiency and optimised purchasing prices. An isolated focus does not do justice to SCM as a cross-functional process - it must be viewed holistically as part of the business process model. According to our experience five fields of action currently deserve special attention. The deepening of the individual subjects outlines the concrete challenges, how we classify them and how they can be mastered.

SCM fields of action

Resilient supply chain

How do we increase the resilience and flexibility of the supply chain to be prepared for volatile times?

Product architecture

How do we design the product architecture to reduce or control complexity in SCM?

Procurement Excellence

How do we improve operational performance through a coherent view of strategic sourcing and operational procurement?

Smart Supply Chain

What is the basis for exploiting the full potential of digitalisation and new technologies?

Sustainable Supply Chain

How do we integrate the sustainability strategy in the supply chain to create sustainable added value for our stakeholders (ESG)?

Individual field of action

Are you concerned about a supply chain issue that we have not yet addressed?

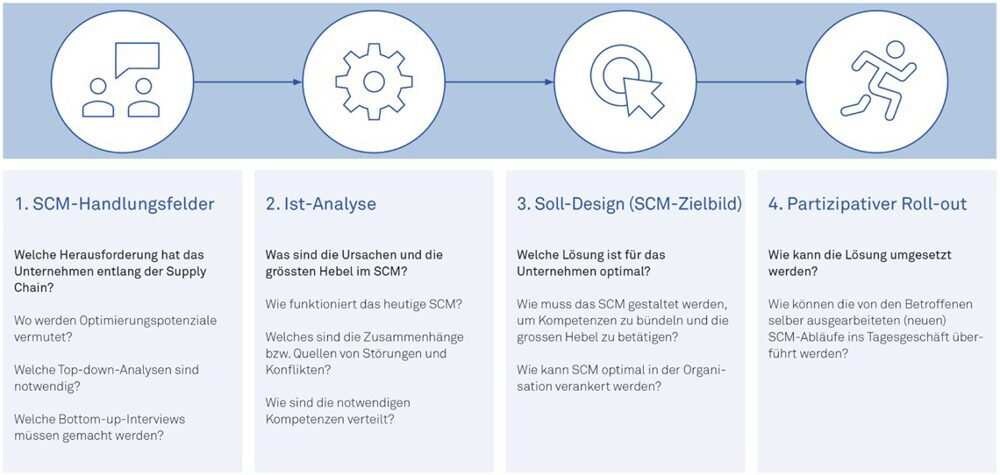

Optimising SCM performance in four steps

Fig. 3: Four steps to high performance supply chain management

Christoph Lanz

Senior Manager